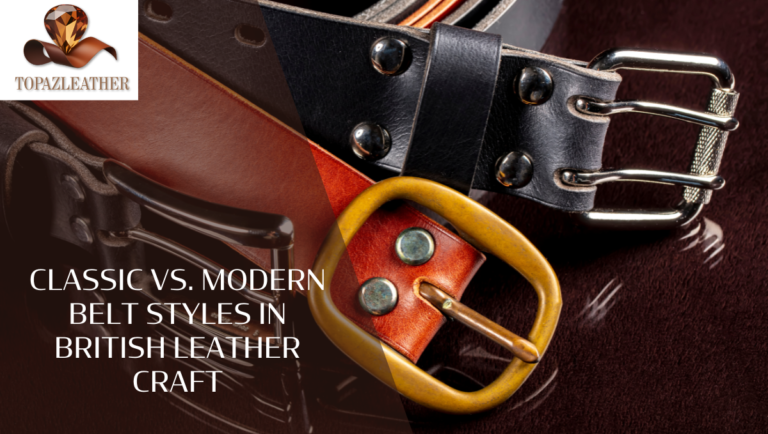

Mirror Finish Leather Edges Perfected on Handmade Belts

Introduction:

Why Mirror-Finish Leather Edges Define True Luxury

Mirror-finish leather edges lend a visual authority to a truly premium leather belt. At Topaz Leather, edge finishing is treated as a disciplined craft rather than a final decorative step. Every edge reflects intention, control, and respect for material, from the first cut to the final polish. Discerning buyers instinctively assess belt quality at the edge, because a flawless edge communicates patience, mastery, and pride in artistry.

British Craftsmanship and the Philosophy Behind Perfect Edges

Topaz Leather achieves mirror-finish leather edges through a heritage-led British methodology rooted in time, restraint, and mastery. Our workshop culture prioritises precision over speed, rejecting shortcuts that compromise refinement. Each belt begins with carefully selected full-grain leather chosen for density, fibre structure, and longevity. This disciplined approach positions our belts among the finest handmade leather goods produced in the UK.

Material Selection: The Foundation of Mirror-Finish Edges

Exceptional mirror-finish leather edges begin with uncompromising material selection. Full-grain leather provides the fibre strength required to withstand repeated shaping, sanding, and burnishing. British leather authorities consistently emphasise preparation as the cornerstone of quality, and our artisans honour this principle by selecting hides that support long-term performance rather than short-term appearance.

Precision Cutting: Establishing Clean Edge Structure

Mirror-finish leather edges demand perfection from the very first cut. Artisans use razor-sharp blades to achieve clean, consistent profiles that preserve fibre integrity. Clean cuts eliminate the need for corrective finishing later, allowing each subsequent stage to build refinement rather than repair flaws. Precision at this stage ensures architectural consistency across the entire belt.

Edge Shaping: Creating Balance and Visual Harmony

Edge shaping defines the architecture of mirror-finish leather edges. Through hand beveling, artisans create a smooth curvature that complements the belt thickness and width. This shaping determines how light interacts with the edge once polished, balancing strength with elegance—even pressure and experienced judgment guide each movement, reinforcing the understated sophistication expected of luxury belts.

Progressive Sanding: Refinement Without Fibre Damage

Sanding transforms shaped edges into refined surfaces ready for sealing. Topaz Leather artisans sand progressively, moving through finer grits to compress fibres rather than tear them. This gradual refinement strengthens the edge and prepares it for burnishing. Institutions such as the Leather Conservation Centre emphasise the importance of fibre integrity forlongevity, a principle reflected in our controlled sanding process.

Controlled Moisture: Activating Natural Leather Oils

Water plays a subtle yet critical role in producing mirror-finish leather edges. Artisans introduce minimal moisture to activate the leather’s natural oils, allowing fibres to bind smoothly under friction. Moisture is carefully regulated to prevent swelling or distortion. This balance separates master craftsmanship from amateur finishing and ensures structural stability.

Traditional Burnishing: Creating the First Reflective Sheen

Burnishing elevates mirror-finish leather edges from smooth to luminous. Using traditional tools, artisans apply friction, heat, and pressure to compress fibres further and create the initial reflective gloss. British craft institutions recognise burnishing as a hallmark of traditional leatherworking, and our workshop preserves this technique with reverence and precision.

Natural Wax Enrichment: Depth Without Compromise

Natural wax compounds enrich mirror-finish leather edges during advanced finishing stages. Topaz Leather selects waxes that nourish fibres rather than mask them, enhancing colour depth and gloss without restricting breathability. This approach aligns with responsible finishing standards promoted by organisations such as the Leather Working Group and supports sustainable luxury production.

Hand Polishing: The Final Expression of Mastery

Hand polishing defines the final character of mirror-finish leather edges. Artisans polish repeatedly using controlled, deliberate strokes that build clarity and depth. This stage demands patience and experience, as over-polishing compromises balance. Machines cannot replicate the nuanced judgment required to stop precisely at perfection.

Colour Harmony: Maintaining Visual Integrity

Colour consistency is essential to achieving mirror-finish leather edges that feel intentional rather than ornamental. Artisans blend edge dyes meticulously to match the belt leather, applying colour gradually to maintain tonal harmony. UK fashion authorities consistently identify colour integrity as a key marker of luxury leather goods.

Natural Drying: Preserving Gloss and Structure

Drying time protects the integrity of mirror-finish leather edges. Topaz Leather allows edges to rest naturally between stages, stabilising fibres and preventing cracking or dullness. Rushed production undermines longevity, while patient pacing ensures edges retain their gloss through years of wear.

Final Inspection: Assurance of Consistency and Quality

Inspection ensures every example of mirror-finish leather edges meets our exacting standards. Artisans examine edges under varied lighting to confirm uniformity, reflectivity, and durability. This mirrors quality assurance principles promoted by British Standards bodies, reinforcing trust through consistency.

Heritage Influence: Timeless British Restraint

Heritage influences every decision behind mirror-finish leather edges at Topaz Leather. British leatherworking traditions value refinement over excess, resulting in clean edges that complement classic silhouettes. Historical leather artefacts preserved by institutions such as the Victoria and Albert Museum demonstrate this enduring aesthetic, which our belts continue today.

Durability: Beauty That Endures Daily Wear

Durability underpins the beauty of mirror-finish leather edges. Compression and sealing protect edges from moisture ingress, abrasion, and fraying. This protection extends the belt’s lifespan while maintaining visual authority, even under daily use.

Ethical Craftsmanship and Responsible Production

Ethical production strengthens trust in mirror-finish leather edges. Topaz Leather sources hides responsibly and minimises waste through precise cutting and disciplined processes. Sustainability organisations such as WRAP UK advocate waste reduction within fashion manufacturing, principles embedded in our workshop practices.

Tactile Refinement: Comfort Meets Craft

The tactile experience of mirror-finish leather edges enhances everyday wear. Smooth edges glide against clothing without snagging, reinforcing comfort alongside aesthetics. This functional refinement supports premium positioning and elevates user satisfaction.

Contemporary Versatility: Designed for Modern Lifestyles

Modern expectations influence how mirror-finish leather edges integrate into contemporary belt design. Consumers seek belts that transition effortlessly between formal and casual settings. Polished edges provide versatility and sophistication without ostentation.

Craft Education: Preserving Excellence for the Future

Craft education sustains excellence in mirror-finish leather edges. Topaz Leather invests in skill development through mentorship and repetition. Heritage organisations such as the Heritage Crafts Association emphasise knowledge transfer, ensuring these techniques endure across generations.

British Manufacturing Standards and Provenance

British manufacturing standards reinforce the credibility of mirror-finish leather edges. UK-made leather goods benefit from strict quality expectations and transparent practices, offering assurance to discerning buyers who value provenance alongside performance.

Conclusion: Edges That Reflect Mastery

Every Topaz Leather belt demonstrates how mirror-finish leather edges represent mastery rather than decoration. Each edge tells a story of patience, discipline, and respect for tradition. This philosophy distinguishes our belts within a competitive market and confirms our commitment to enduring quality.

Call to Action

Experience belts defined by mirror-finish leather edges, crafted with British heritage and uncompromising precision.

Speak directly with our artisans and commission a belt that reflects timeless quality and refined detail.

FAQs

Mirror-finished edges offer enhanced durability, refined appearance, and long-term resistance to wear through compression and polishing.

Edges require minimal maintenance, benefiting from occasional conditioning and storage away from excessive moisture.

Appropriately crafted mirror-finish edges maintain gloss and integrity for many years with regular use.

Yes. Artisans rely on manual techniques and natural compounds that support sustainable production.

Edge refinement signals craftsmanship, longevity, and attention to detail that mass production cannot replicate.